We can say that the “digital twins” are actually a product of the space age and a futurist concept, since it was first successfully introduced by NASA to create simulations or “duplicates” of the real-world spacecrafts and capsules, so the testing would be done on twins, not on real-life objects. A digital twin of a physical object, process or service from the real world is a digital recreation or simulation – to the minutest detail. It is a digital, virtual replica – it could range from simple things like mobile phone to e-vehicles, all the way to the whole (smart) cities with all possible infrastructure needed for its functioning. These digital reproductions can serve for monitoring the real world counterparts, repairing the errors and malfunctions, or they can serve as a field of experimentation – we can simulate the changes to improve the “real life twins” and see the results in the virtual world.

Who have adopted digital twins already?

Just like AI which was a niche idea several years ago, until it was everywhere, the digital twin concept was at first highly specific in use, and in 2023 and 2024 it became widespread. In 2023, according to the data from Statista, 15% of the real estate companies around the globe used digital twins of the houses and buildings. Gartner estimates that by 2027, over 40% of large companies worldwide will be using digital-twin concepts in their projects to increase revenue.

McKinsey’s data claim that the product development leaders need digital twins as a tool to speed up the process of product development, reducing costs and eliminate errors, in order to enhance the results and profits and improve outcomes. Their forecast is that the investment in the concept of digital twins will rise by a whopping 60% annually, reaching $73.5 billion by 2027. It means that the digital twins are a new “goldmine”, if you ask the product developers and company thinkers.

The forecast of product developer leaders is that the investment in the concept of digital twins will rise by a whopping 60% annually, reaching $73.5 billion by 2027.

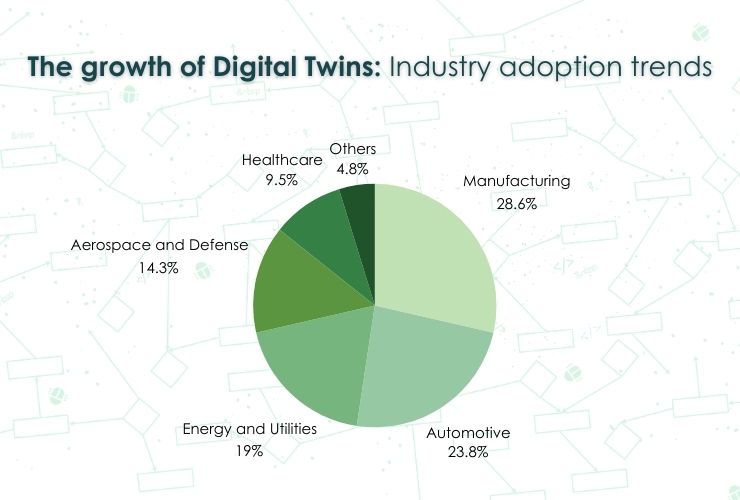

There is a lot of disparities in the digital twin adoption since the more advanced industries like energy, infrastructure, logistic etc. have a higher adoption rate – the McKinsey’s data show that almost 75% of these companies have already adopted the concept, at least at medium levels of complexity. It is especially so in defence industries, automotive and spacecraft industries, who are at the helm of the adoption process. They tend to expand the use of the concept at the levels of higher complexity, while the energy companies, logistic companies and those dealing with infrastructure tend to develop and use their first digital-twin concepts and use the lower levels of complexity. But soon they will follow the footsteps of the most advanced industries.

Impressive 75% of the advanced industries have already adopted at least medium-level digital-twin concepts while the most popular and omnipresent industries like energy, infrastructure, logistic etc. are currently adopting their first digital-twin concepts at low complexity levels

When should you adopt the digital-twin concept?

Most companies tend to launch new products to keep their competitiveness and keep up with the competition. Yet estimation from McKinsey says that $30 trillion of revenue in the next 5 years are going to be attributed to the products that do not exist yet. And the digital-twin concept is a risk-free tool to make all the necessary changes before the product is launched, thus sparing millions that could be lost because of the product’s potential shortcomings.

It is the crucial future tool for R&D sectors in companies that will allow them to test all the possible options they could imagine before they make an actual physical prototype. The concept also enables the R&D teams to test the developing product in extreme or unusual circumstances.

The R&D teams can make all the necessary changes to the product before the actual physical prototype is produced

In fact, the impact in R&D is so huge that the time spent for development of a prototype is shortened any way from 20% to 50% and the number of actual physical prototypes is cut from 3 or 2 to just one before the mass production starts.

It can also enable real-time and long-distance virtual repairs to some product or services, and it can increase the revenue from the product developed by digital-twin concept by 3-5% while it can go as high as 5-10% if the product has some value-added features.

The revenues from product developed by implementation of a digital-twin concept can reach from 3% to 10%, depending from the degree of value-added features embedded

It is the thing of future, but it has already arrived. It can give you a competitive advantage and cut the R&D costs and time and give you an opportunity to offer a better suited product that the customers will love.

Ready to take the next step?

Let's explore how our expertise can help you innovate and implement your vision in a digital world.

Reach out to us:ICodeFactory | Contact